产品型号

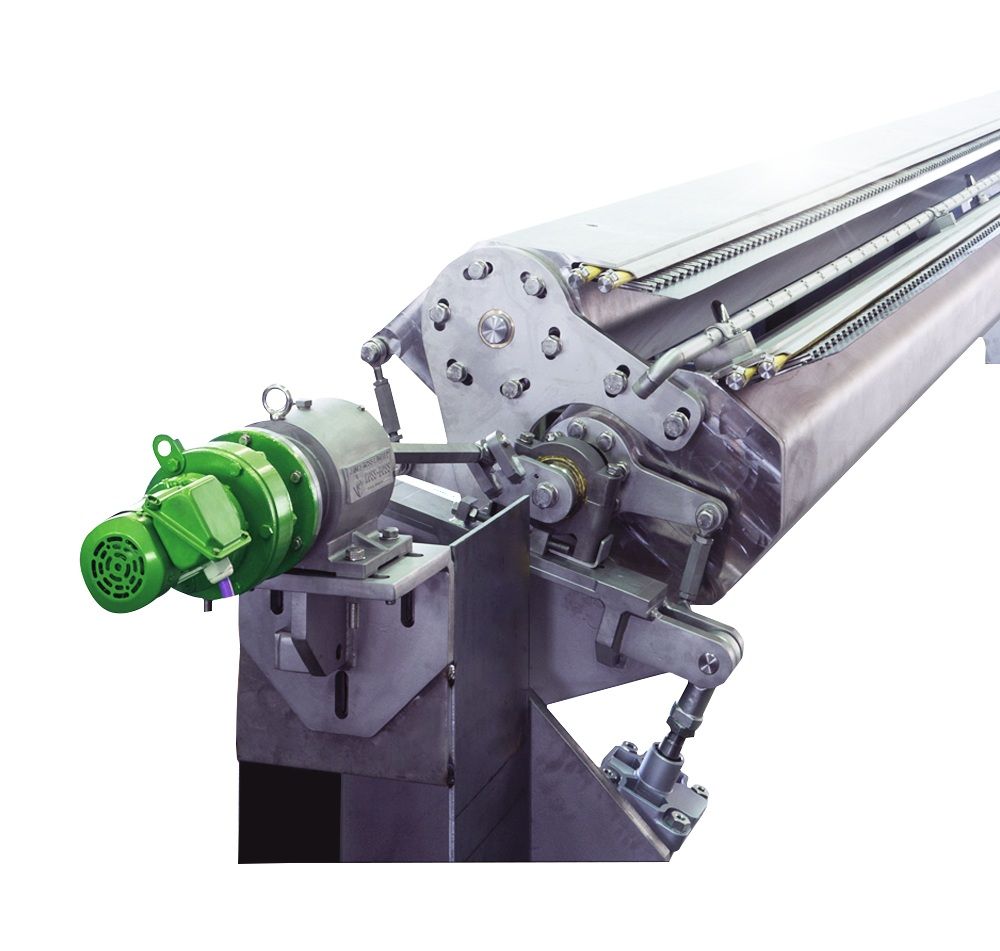

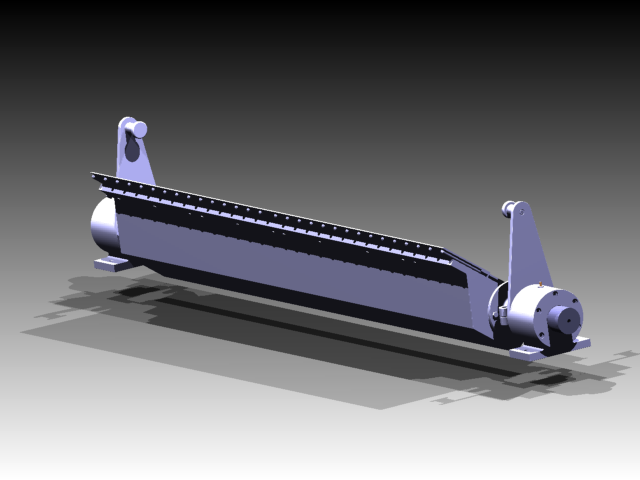

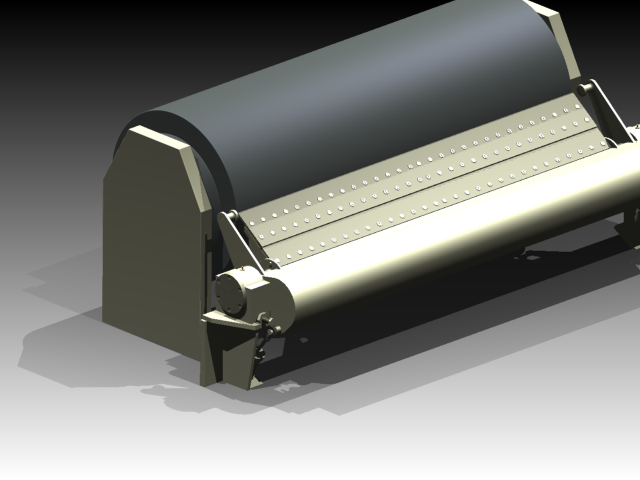

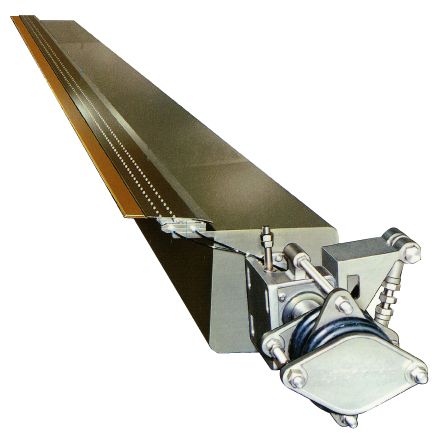

YZX-DBS 双刮刀装置(双刮刀气囊加压控制式)

详细介绍

双刮刀是两台双气囊刮刀合用的方式。目的是为了去除附着在辊面上的水分及脏东西为目的。使用过程中,棍子表面上会有许多凹凸不平的小孔,刀刃的磨擦面也会有同样现象。因而,微小的脏东西及水分就会透过这些小孔,顺流到刮刀后表面。由于脏东西有些被纸张带走,另一些粘结在刮刀背后形成块状物,许久过后容易掉下,从而造成断纸,以致停机。特别是压榨部的石辊等,此现象比较严重。除此之外,刮刀片施加较大的线压时,会在刀片背后产生负压,这个负压会造成在刀片正面堆积许多脏东西,也会严重地影响产品质量。

在中心压榨部、网部伏辊等加装双刮刀。利用离心力的作用,伏辊、真空压辊孔内水及细小纤维非出并附着于辊第一刮刀能破坏其表面张力,清除部分水及细小纤维,并在刮刀之后形成微小负压将孔内水及细小纤维彻底排出后由第二刮刀清理。

双气囊刮刀可以有效的解决这些问题,在保持线压、材质和角度问题的基础上,保持辊面的运行清洁,减少断头及纸病,并有效保护辊面,延长棍子的使用寿命,减少停机更换维护的频率,提高经济效益。

YZX-DAS Double-Blade Device(Double Blades Air Cell Pressure Control)

The double-blade device, made up by two air-cell blades, it means using two air-cell blades at the same time. It is used to remove the moisture and dirt attached to the roller surface. During the operation, plenty of pores will form on the roller surface as well as on the abrasive side of edge. Therefore, small dirt and moisture will enter into the back surface of blade through these pores. Some dirt will be taken away be paper, while some will attach to the back of blade, forming lumps which will drop after a long time, thus causing paper breakage and even machine halt. Such condition is even more serious for the stone roller in the press section. In addition, a great lineal pressure exerted by the blade may produce negative pressure at the back of blade which causes plenty of dirt to gather on the front of blade, thus seriously affecting product quality.

The double-blade device is equipped in the central press section, couch roll in the net section and so on. Under the action of centrifugal force, the moisture and fine fibers will be thrown away from the pores of couch roll and vacuum compression roller, and then attach to the first blade which is able to destroy their surface tension, remove part of moisture and fine fibers and form a small negative pressure behind the blade. The second blade will clear away the moisture and fine fibers expelled from the pores by the small negative pressure.

The double air-cell blades can effectively solve these problems. It is able to keep the roller surface clean while maintaining a proper lineal pressure and angle and protecting materials. Besides, it can reduce ends down and paper defects, effectively protect roller surface, prolong the service life of roller, and reduce the frequency of shutdown for replacement and maintenance, thus improving the economic benefit.

双刮刀是两台双气囊刮刀合用的方式。目的是为了去除附着在辊面上的水分及脏东西为目的。使用过程中,棍子表面上会有许多凹凸不平的小孔,刀刃的磨擦面也会有同样现象。因而,微小的脏东西及水分就会透过这些小孔,顺流到刮刀后表面。由于脏东西有些被纸张带走,另一些粘结在刮刀背后形成块状物,许久过后容易掉下,从而造成断纸,以致停机。特别是压榨部的石辊等,此现象比较严重。除此之外,刮刀片施加较大的线压时,会在刀片背后产生负压,这个负压会造成在刀片正面堆积许多脏东西,也会严重地影响产品质量。

在中心压榨部、网部伏辊等加装双刮刀。利用离心力的作用,伏辊、真空压辊孔内水及细小纤维非出并附着于辊第一刮刀能破坏其表面张力,清除部分水及细小纤维,并在刮刀之后形成微小负压将孔内水及细小纤维彻底排出后由第二刮刀清理。

双气囊刮刀可以有效的解决这些问题,在保持线压、材质和角度问题的基础上,保持辊面的运行清洁,减少断头及纸病,并有效保护辊面,延长棍子的使用寿命,减少停机更换维护的频率,提高经济效益。